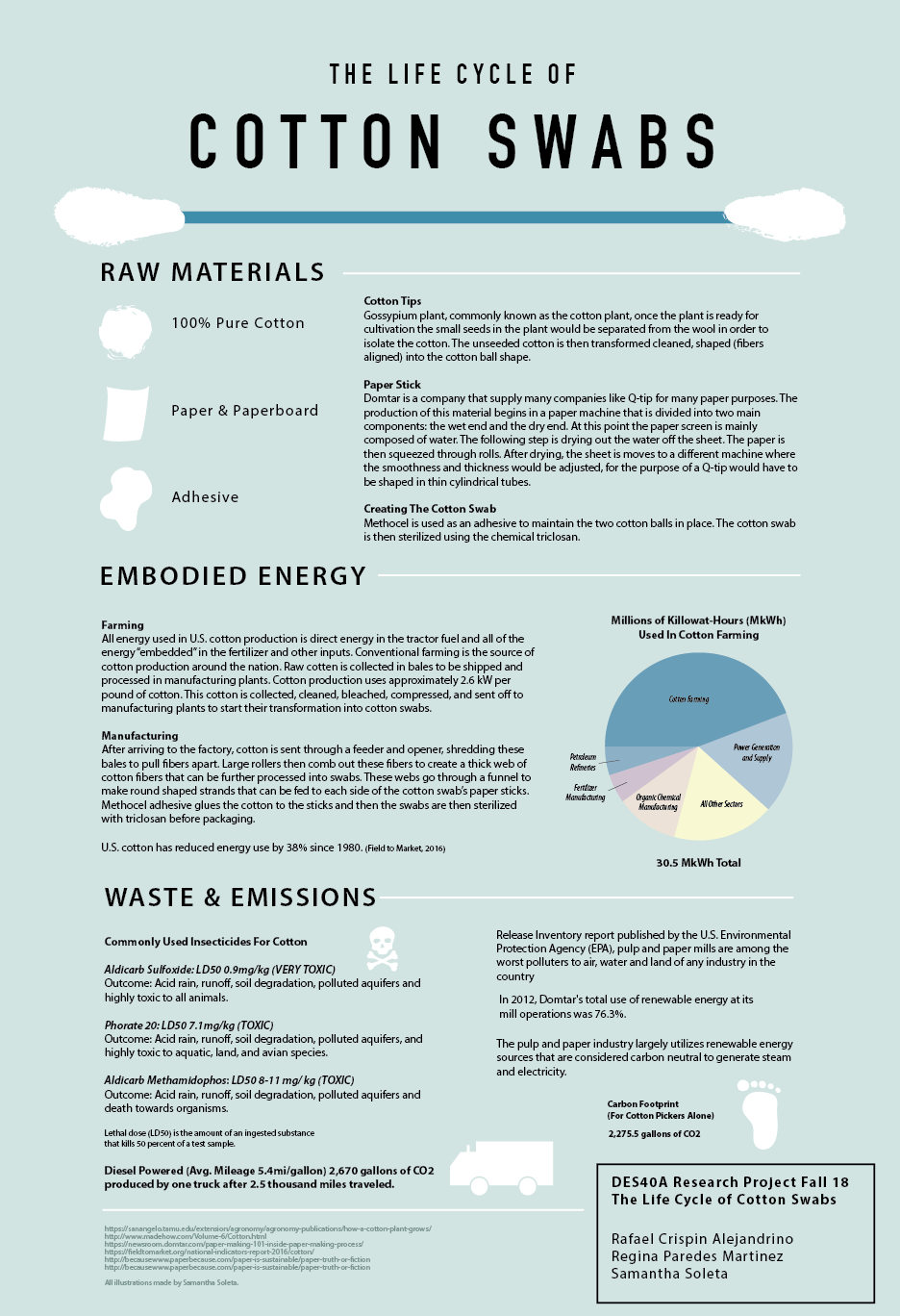

Alt text: Complete lifecycle of cotton swabs from raw materials to finished products

Have you ever wondered what goes into making the simple cotton swab you use every day? While these small hygiene tools appear straightforward, the reality behind cotton swab manufacturers reveals a fascinating world of precision engineering, material science, and quality control that most consumers never see.

Every day, millions of people reach for cotton swabs without considering their composition. Yet behind each perfectly formed swab lies a complex manufacturing process involving carefully selected materials, advanced machinery, and strict quality standards. From the cotton fibers that form the soft tips to the adhesives that hold everything together, every component plays a crucial role in creating products that meet diverse consumer needs worldwide.

The Hidden World Behind Cotton Swab Manufacturing

Most consumers view cotton swabs as simple, disposable items, but cotton buds manufacturer companies operate in a highly competitive market where material quality, production efficiency, and product differentiation determine success. The complexity begins with understanding that not all cotton swabs are created equal, and materials used vary significantly depending on intended applications and target markets.

Modern cotton swab manufacturing serves diverse markets, from basic household cleaning to specialized medical applications, cosmetic precision work, and baby care products. Each market segment demands specific material properties, safety standards, and performance characteristics that influence every aspect of manufacturing, from raw material selection to final packaging.

What Goes Into Making Quality Cotton Swabs: A Complete Breakdown

Quality cotton swabs depend on five essential material categories working together to create the final product:

- Cotton fiber material – The absorbent, soft tip that contacts surfaces

- Stick material – The structural backbone providing strength and handling

- Adhesive systems – The bonding agents securing cotton to stick

- Antimicrobial treatments – Optional protective coatings for enhanced hygiene

- Packaging materials – Protective containers and branding solutions

Professional cotton swab manufacturers understand that compromising on any single component affects the entire product’s performance, safety, and market acceptance.

100% Pure Cotton: The Heart of Premium Cotton Swabs

The cotton fiber used in cotton swab tips represents the most critical material component, directly affecting product performance, safety, and user experience. While many manufacturers use cotton blends or synthetic alternatives to reduce costs, premium cotton buds manufacturer companies recognize that 100% pure cotton provides superior performance characteristics.

Pure cotton fibers offer exceptional absorbency, holding up to 25 times their weight in liquid while maintaining structural integrity. This absorbency comes from cotton’s natural cellular structure, which contains numerous microscopic spaces that trap and hold liquids effectively. When compared to synthetic alternatives, pure cotton demonstrates superior liquid retention and release properties ideal for cleaning, cosmetic application, and medical uses.

The softness of 100% pure cotton provides crucial advantages, particularly for applications involving sensitive skin or delicate surfaces. Cotton’s natural fiber structure creates a gentle texture that effectively removes debris and applies products without causing irritation or scratching. This characteristic becomes especially important for baby care products and cosmetic applications where user comfort and safety are paramount.

Professional manufacturers serving mid-to-high-end markets understand that cotton quality directly impacts brand reputation and customer satisfaction. Premium cotton fibers undergo extensive processing to remove impurities, achieve consistent fiber length, and ensure uniform color and texture.

Stick Materials: From Bamboo to Paper – What Cotton Swab Manufacturers Choose

The stick material forms the structural foundation of every cotton swab, providing strength, flexibility, and handling characteristics that determine user experience and product performance. Modern cotton swab manufacturers offer multiple stick material options to meet diverse customer requirements, environmental regulations, and market preferences.

Bamboo Stick Cotton Buds: The Sustainable Choice

Bamboo has emerged as a leading sustainable alternative for cotton swab sticks, offering excellent environmental benefits and performance characteristics. As a rapidly renewable resource, bamboo can be harvested without killing the plant, allowing continuous production cycles that support sustainable manufacturing practices.

The mechanical properties of bamboo make it well-suited for cotton swab applications. Bamboo fibers provide excellent tensile strength, allowing thin stick profiles that maintain structural integrity during use. The natural flexibility of bamboo creates sticks that bend slightly under pressure without breaking, providing user feedback that helps prevent excessive force application.

Wooden Stick Cotton Buds: Traditional Strength and Precision

Alt text: High-quality bamboo stick cotton buds showing 100% pure cotton tips

Wood remains popular for cotton swab sticks, particularly in applications requiring maximum strength and precision. Traditional wooden sticks offer excellent dimensional stability, superior strength characteristics, and proven performance across diverse applications. Birch wood provides excellent strength and smooth surface characteristics, making it popular for precision applications.

Paper Stick Cotton Buds: Biodegradable Innovation

Paper sticks represent the newest innovation in cotton swab manufacturing, offering complete biodegradability and minimal environmental impact. As environmental regulations become more stringent and consumer awareness of plastic pollution increases, cotton buds manufacturer companies are investing heavily in paper stick technology.

Modern paper sticks incorporate multiple paper layers, specialized adhesives, and surface treatments that provide adequate strength while maintaining biodegradability. The development required significant innovation in paper manufacturing and processing techniques to achieve the strength and moisture resistance needed for cotton swab applications.

Specialized Cotton Swabs: Baby Care and Cosmetic Applications

Baby Cotton Buds: Safety-First Design for Delicate Care

Alt text: Specialized baby cotton swabs with safety features and gentle design

Baby cotton swabs represent one of the most safety-critical applications, requiring specialized design features and materials that prioritize infant safety. The most distinctive feature is the enlarged cotton tip design that prevents deep insertion into ears or nostrils, addressing the primary risk associated with cotton swab use in infants.

Material selection emphasizes hypoallergenic properties and chemical safety. The cotton must be free from chemical residues, dyes, or processing agents that could cause allergic reactions. Many manufacturers use organic cotton or specially processed cotton meeting stringent purity standards.

Cosmetic Cotton Buds: Precision Tools for Beauty Professionals

Alt text: Precision cosmetic cotton swabs designed for detailed makeup application

Cosmetic cotton swabs serve the beauty industry’s need for precision application and removal tools. These specialized products require design characteristics that prioritize control, precision, and versatility. The cotton tip design often features pointed or tapered shapes enabling precise application and removal of makeup products.

The Secret Adhesive: Why Premium Manufacturers Choose KURARAY PVOH

The adhesive system represents one of the most critical yet least understood components. Professional cotton swab manufacturers understand that adhesive selection directly impacts product safety, performance, and reliability. Among advanced adhesive technologies, KURARAY’s Polyvinyl Alcohol (PVOH) has emerged as the preferred choice for manufacturers serving mid-to-high-end markets.

KURARAY Co., Ltd., a Japanese chemical company with over 90 years of experience, has developed PVOH technology that sets industry standards for performance and safety. KURARAY’s POVAL™ brand represents one of the most advanced polyvinyl alcohol formulations available, offering characteristics specifically suited for demanding applications like cotton swab manufacturing.

Polyvinyl alcohol differs fundamentally from conventional adhesives in its molecular structure and bonding characteristics. PVOH forms strong hydrogen bonds with cotton fibers while maintaining flexibility and resistance to environmental factors. The water-soluble nature provides unique advantages, as PVOH can be dissolved if necessary, reducing the risk of permanent adhesive residue in sensitive applications.

The safety profile of KURARAY PVOH makes it particularly suitable for personal care and medical applications where user safety is paramount. PVOH is recognized as safe for contact with skin and mucous membranes, meeting stringent safety standards required for personal care products.

Antimicrobial Protection: Chitosan and PHMB in Modern Cotton Swabs

The integration of antimicrobial treatments addresses growing consumer concerns about bacterial contamination and infection prevention. The two primary antimicrobial agents used are chitosan and PHMB (Polyhexamethylene Biguanide), each offering distinct advantages.

Chitosan represents a natural antimicrobial option derived from chitin, found in crustacean shells. As a naturally occurring biopolymer, chitosan offers antimicrobial properties while maintaining environmental compatibility. The antimicrobial mechanism involves disruption of bacterial cell membranes, providing broad-spectrum activity against bacteria, fungi, and some viruses.

PHMB represents a synthetic antimicrobial agent providing broad-spectrum protection. PHMB has been extensively used in medical applications, establishing a proven track record of safety and effectiveness. The synthetic nature enables precise control over antimicrobial properties and consistent performance characteristics.

Packaging That Protects: From PP Containers to Custom Branding

Alt text: Various eco-friendly packaging options for cotton swabs including recycled cardboard and sustainable materials

Modern cotton swab manufacturers recognize that packaging decisions significantly impact product success, customer satisfaction, and brand positioning. The choice of packaging materials affects manufacturing costs, environmental impact, and market acceptance.

PP Container Packaging offers excellent protection, durability, and cost-effectiveness. PP containers provide superior moisture protection and chemical resistance, making them suitable for products requiring extended shelf life.

Paper Box Packaging represents an environmentally responsible option appealing to consumers seeking sustainable alternatives. Paper boxes offer adequate protection while providing complete biodegradability and recyclability.

PE Bag Packaging offers cost-effective solutions providing adequate protection while minimizing material costs. PE bags are particularly suitable for bulk packaging applications or cost-sensitive markets.

Custom Branding Solutions through paper stickers and printed PVC shrink labels enable distinctive product identities supporting marketing objectives and brand differentiation.

Why Choose Professional Cotton Swab Manufacturers

Professional manufacturers bring expertise, capabilities, and resources enabling high-quality cotton swab production that meets demanding market requirements. The complexity of modern manufacturing requires specialized knowledge, equipment, and quality control systems not easily replicated by smaller manufacturers.

Professional cotton buds manufacturer companies invest heavily in technology, training, and process development to maintain competitive advantages and deliver consistent product quality. These investments create barriers to entry while providing value to customers through superior materials, manufacturing excellence, and reliable supply chains.

The Complete Picture: Quality Materials Make Quality Cotton Swabs

Understanding the materials and manufacturing processes behind cotton swabs reveals why some products perform significantly better than others. Material selection emerges as the foundation of quality, with decisions about cotton purity, stick materials, adhesive systems, and optional treatments directly affecting performance, safety, and market positioning.

The choice to use premium materials like 100% pure cotton, sustainable stick materials, and advanced adhesives like KURARAY PVOH reflects a manufacturer’s commitment to quality that resonates with discerning customers and supports premium pricing strategies.

Environmental considerations increasingly influence material selection as consumers and regulators demand more sustainable alternatives. The development of biodegradable stick materials, sustainable packaging options, and environmentally responsible manufacturing processes represents ongoing industry evolution.

For consumers and businesses seeking cotton swab solutions, understanding the materials and manufacturing processes enables informed decisions that balance performance requirements, cost considerations, and environmental preferences. The investment in premium materials and professional manufacturing typically provides superior value through improved performance, enhanced safety, and greater reliability.

References

[1] Forbona Group. “A Complete Guide to Cotton Swab Manufacturing: Process and Machinery.” https://www.forbona.com/news/a-complete-guide-to-cotton-swab-manufacturing-process-and-machinery

[2] KURARAY Co., Ltd. “KURARAY POVAL™ | Polyvinyl alcohol, PVA, PVOH.” https://www.kuraray-poval.com/

[3] Made How. “How cotton swab is made – material, manufacture, making, used.” https://www.madehow.com/Volume-4/Cotton-Swab.html

[4] ScienceDirect. “A systematic review on materials, design, and manufacturing of swabs.” https://www.sciencedirect.com/science/article/pii/S2666964122000467

This article was researched and written by the Swabmasters team, drawing on over 23 years of experience in cotton swab manufacturing and industry expertise. For more information about our premium cotton swab solutions and manufacturing capabilities, visit www.swabmasters.com.