SWABMASTERS Professional Industrial Cotton Swabs – 100 Count Package

Industrial cotton swabs are essential precision tools in modern manufacturing environments. These specialized cleaning instruments play a crucial role in maintaining quality, ensuring reliability, and supporting precision operations across diverse industries. From electronics assembly to aerospace manufacturing, professional cotton swabs deliver the accuracy and performance that demanding applications require.

Table of Contents

- What Makes Industrial Cotton Swabs Different?

- Understanding Different Types of Industrial Swabs

- 19 Professional Cotton Swab Uses in Manufacturing

- Industry-Specific Applications

- Choosing the Right Industrial Cotton Swabs

- Best Practices for Industrial Cotton Swab Use

- Quality Standards and Certifications

- Cost Considerations and ROI

- Conclusion

What Makes Industrial Cotton Swabs Different?

Industrial cotton swabs differ significantly from household versions in both design and performance characteristics. These professional-grade tools are engineered to meet the demanding requirements of manufacturing environments where precision, reliability, and contamination control are paramount.

SWABMASTERS Professional Quality – Superior cotton fiber construction

Key characteristics that distinguish industrial cotton swabs include:

High Absorbency: Professional cotton swabs feature superior absorbent capacity for effective cleaning and precise fluid application. The cotton fibers are specially processed to maximize liquid retention while maintaining structural integrity.

Low Lint Properties: Manufacturing environments require tools that don’t introduce contaminants. Industrial cotton swabs undergo special processing to minimize fiber shedding and particle generation.

Chemical Resistance: Professional swabs must withstand exposure to various solvents, cleaning agents, and industrial chemicals without degrading or leaving residues.

Precision Tips: Manufacturing applications often require access to tight spaces and delicate components. Industrial swabs feature precisely formed tips that maintain their shape under use.

Static Dissipative Options: Electronics manufacturing requires tools that safely dissipate static electricity. ESD-safe cotton swabs protect sensitive components from electrostatic discharge damage.

Sterile Packaging: Cleanroom and pharmaceutical applications demand sterile tools. Professional cotton swabs are available in individually packaged, validated sterile formats.

SWABMASTERS industrial cotton swabs incorporate all these features while maintaining cost-effectiveness for high-volume manufacturing operations. Our rigorous quality control ensures consistent performance across every production lot.

Professional industrial cotton swabs designed for manufacturing applications

Understanding Different Types of Industrial Swabs

Manufacturing applications require different swab materials and designs to address specific cleaning challenges and environmental conditions. Understanding these differences helps ensure optimal tool selection for each application.

Cotton Swabs remain the most popular choice for general industrial applications. Natural cotton fibers provide excellent absorbency and gentle cleaning action. Cotton swabs work effectively with alcohol-based solvents and are cost-effective for single-use applications. They’re ideal for precision cleaning where chemical compatibility isn’t a concern.

Foam Swabs offer superior performance in many industrial applications. Open-cell polyurethane foam provides exceptional absorbency and particle capture capability. The reticulated structure traps contaminants within the foam matrix, preventing redistribution during cleaning. Foam swabs don’t leave fibers behind, making them ideal for cleanroom applications.

Polyester Swabs deliver exceptional chemical resistance and mechanical durability. Knitted polyester construction withstands aggressive solvents and provides superior scrubbing ability. These swabs excel at removing stubborn residues like cured adhesives, flux deposits, and coating materials.

Wrapped Swabs feature encapsulated tips that eliminate loose fibers completely. The wrapped construction prevents particle generation while maintaining cleaning effectiveness. These premium swabs are essential for the most demanding contamination-sensitive applications.

Microfiber Swabs combine the benefits of synthetic materials with enhanced cleaning performance. The ultra-fine fibers capture microscopic particles effectively while providing excellent chemical compatibility.

19 Professional Cotton Swab Uses in Manufacturing

1. Precision Component Cleaning

Manufacturing success depends on spotless components that perform reliably throughout their service life. Industrial cotton swabs excel at removing contaminants from delicate parts without causing surface damage or leaving residues. The soft cotton tips conform to irregular geometries while effectively capturing dust particles, fingerprint oils, and manufacturing residues.

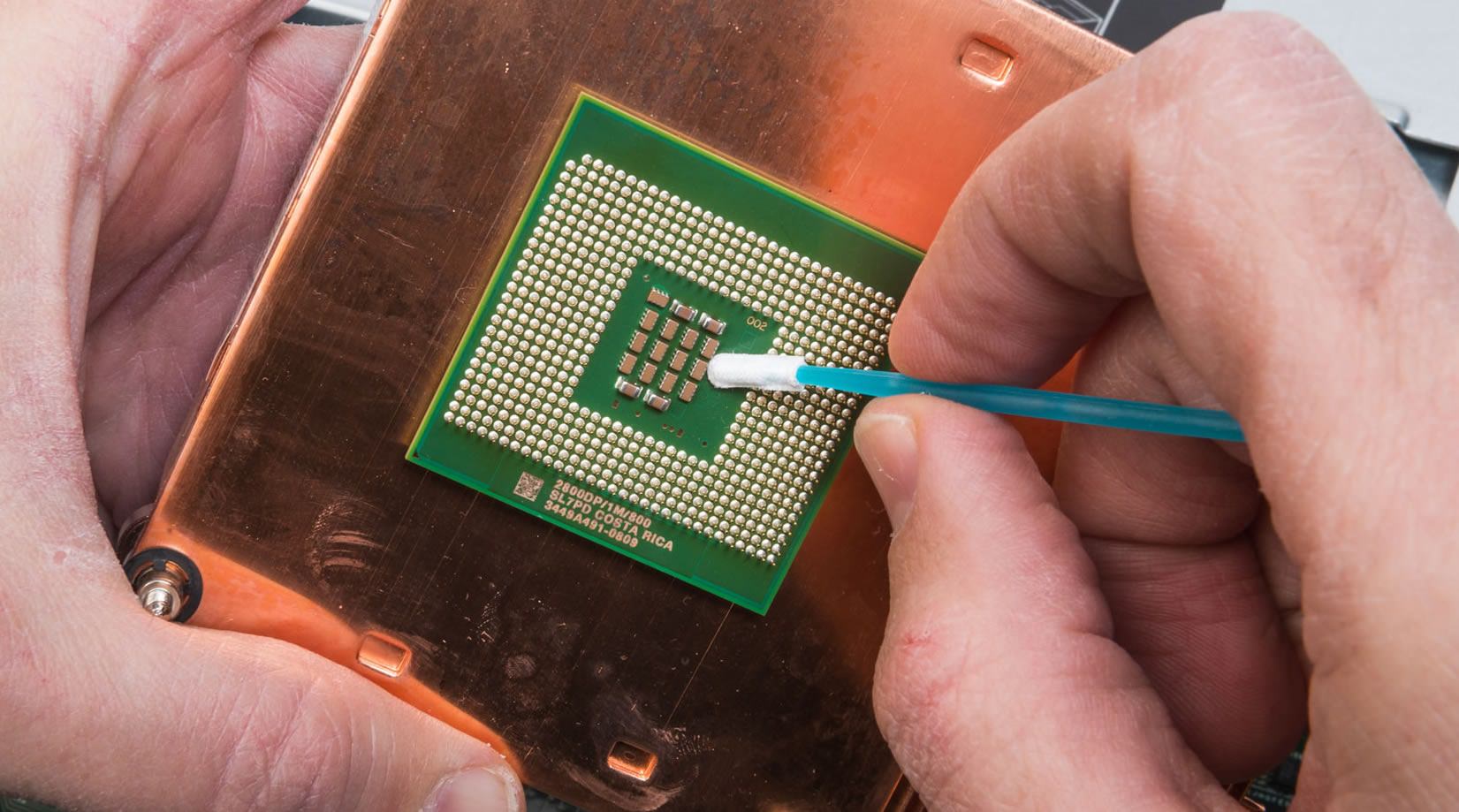

Professional technician using SWABMASTERS cotton swabs for precision electronics cleaning

SWABMASTERS precision cleaning swabs feature ultra-fine cotton tips that penetrate microscopic surface features and crevices. These tools are essential for preparing surfaces before critical operations like coating application, adhesive bonding, or precision assembly. Clean components ensure proper material adhesion and prevent premature failure modes.

The cleaning process requires careful technique to avoid redistributing contaminants. Cotton swabs enable controlled cleaning motions that lift particles away from surfaces rather than spreading them around. This precision is particularly important when cleaning optical components, sensor surfaces, and precision mechanical parts.

2. Lubricant Application

Precise lubricant application is critical for manufacturing equipment reliability and product quality. Cotton swabs enable controlled delivery of oils, greases, and specialized lubricants to specific locations without waste or contamination of surrounding areas. This targeted approach prevents over-lubrication while ensuring adequate protection for moving components.

Manufacturing technicians rely on cotton swabs to apply lubricants to bearings, sliding mechanisms, gear teeth, and pivot points. The absorbent cotton tip holds the exact amount of lubricant needed while the rigid handle provides precise positioning control. This method reduces material waste and improves application consistency compared to spray or brush methods.

Different lubricant types require specific application techniques. Light oils can be applied directly from the swab tip, while heavier greases may require warming or working to achieve proper consistency. Cotton swabs accommodate these variations while maintaining application precision.

3. Adhesive Application

Modern manufacturing relies extensively on adhesives for component assembly and sealing applications. Cotton swabs enable precise adhesive placement in confined spaces where conventional dispensing equipment cannot reach. This accuracy is crucial for electronics assembly, optical component mounting, and precision mechanical assemblies.

The controlled application prevents adhesive overflow that could interfere with nearby components or create unwanted bonds. SWABMASTERS adhesive application swabs feature specially designed tips that release adhesive evenly while maintaining precise control over placement and quantity.

Adhesive application with cotton swabs requires understanding of working time and cure characteristics. Fast-setting adhesives demand quick, accurate placement, while structural adhesives allow more time for positioning. The swab technique must match the adhesive properties to achieve optimal results.

4. Flux Residue Removal

Electronics manufacturing generates flux residues that must be completely removed to prevent corrosion and electrical failures. These residues are often acidic and can cause long-term reliability problems if not properly cleaned. Industrial cotton swabs with appropriate solvents provide effective flux removal without damaging delicate electronic components.

Professional cotton swab being used for precision electronics cleaning

The cleaning process requires gentle yet thorough action to remove all flux residues without disturbing component placement or damaging solder joints. Cotton swabs provide the ideal balance of cleaning effectiveness and component protection. They remove flux deposits without leaving behind fibers that could cause electrical shorts.

Different flux types require specific cleaning solvents and techniques. Water-soluble fluxes can be removed with deionized water, while rosin-based fluxes require alcohol or specialized flux removers. Cotton swabs work effectively with all these cleaning agents while providing precise application control.

5. Static Control Applications

Static electricity poses serious risks in electronics manufacturing environments. Electrostatic discharge can damage sensitive components instantly, causing immediate failure or latent defects that appear later in service. ESD-safe cotton swabs feature conductive handles that safely dissipate static charges during cleaning and maintenance operations.

Static dissipative swabs prevent damage to microprocessors, memory devices, and other sensitive electronic components. The conductive properties ensure that any static buildup is safely channeled away from critical circuits. This protection is essential in cleanroom environments where humidity control may not be sufficient to prevent static accumulation.

Proper use of ESD-safe swabs requires understanding of grounding techniques and static control procedures. The conductive handle must be properly connected to ground potential to provide effective protection. Training in electrostatic discharge principles is essential for personnel using these specialized tools.

6. Surface Sampling for Quality Control

Quality control processes require accurate contamination detection to ensure manufacturing standards are maintained. Cotton swabs provide an effective method for collecting surface samples for laboratory analysis. This testing identifies contamination sources and verifies cleaning effectiveness.

Sampling swabs must be sterile and free from contaminants that could affect analytical results. SWABMASTERS quality control swabs undergo rigorous validation to ensure they don’t introduce false positives or interfere with analytical procedures. The cotton tips efficiently collect particles and residues while maintaining sample integrity.

Proper sampling technique is critical for obtaining representative results. The swab must contact the entire sampling area with consistent pressure and motion. Documentation of sampling procedures ensures reproducible results and regulatory compliance.

7. Sealant Application in Aerospace Manufacturing

Aerospace manufacturing demands precise sealant application for safety-critical applications where leaks could have catastrophic consequences. Cotton swabs enable controlled placement of sealants in complex geometries and confined spaces where conventional application methods are impractical.

Specialized foam swabs designed for aerospace and precision manufacturing applications

Aerospace-grade sealants often have limited working time and require immediate, accurate placement. Cotton swabs allow technicians to work sealant into complex joint configurations and ensure complete coverage without excess material. The precision application prevents waste of expensive aerospace materials while maintaining stringent quality standards.

Different sealant chemistries require specific application techniques and curing conditions. Silicone sealants may require surface preparation with primers, while polysulfide sealants need protection from moisture during cure. Cotton swabs accommodate these requirements while providing consistent application results.

8. Touch-up Painting

Manufacturing operations often require touch-up painting for cosmetic correction or corrosion protection. Cotton swabs provide precise paint application for small areas and detail work where brushes would be too large or imprecise. This capability is essential for maintaining product appearance standards and preventing corrosion initiation.

The absorbent cotton tip holds paint effectively while allowing controlled release during application. This precision prevents overspray and ensures clean, professional results. Touch-up work with cotton swabs is faster and more accurate than masking and spray methods for small areas.

Paint compatibility with cotton fibers must be considered to prevent adverse reactions. Water-based paints generally work well with cotton, while some solvent-based paints may require synthetic swab materials. Testing compatibility before production use prevents quality problems.

9. Optical Equipment Cleaning

Optical components require specialized cleaning to maintain performance and prevent damage to expensive coatings. Cotton swabs with appropriate solvents remove fingerprints, dust, and other contaminants from lenses, mirrors, and prisms without scratching delicate surfaces.

Manufacturing equipment increasingly incorporates optical sensors, cameras, and measurement systems that require regular maintenance. Cotton swabs provide the gentle cleaning action needed to preserve optical coatings while ensuring measurement accuracy. Clean optics are essential for reliable automated inspection and quality control.

Optical cleaning requires understanding of coating types and compatible cleaning agents. Anti-reflection coatings may be damaged by alkaline cleaners, while some solvents can dissolve protective coatings. Proper cleaning procedures prevent expensive optical component damage.

10. PCB Maintenance and Repair

Printed circuit board manufacturing and repair operations require precise cleaning tools that can access tight spaces between components. Cotton swabs remove solder flux, clean component pads, and prepare surfaces for rework operations without damaging delicate traces or components.

PCB cleaning applications require different solvents for different contamination types. Flux residues typically require alcohol-based cleaners, while adhesive residues may need stronger solvents. Cotton swabs work effectively with all these cleaning agents while providing precise application control.

The cleaning process must avoid spreading contaminants to clean areas of the circuit board. Cotton swabs enable controlled cleaning motions that lift contaminants away from the surface rather than redistributing them. This precision is essential for maintaining circuit reliability.

11. Automotive Manufacturing Applications

Automotive manufacturing combines traditional mechanical systems with sophisticated electronic components. This combination requires versatile cleaning tools that work effectively on both metallic and electronic surfaces. Industrial cotton swabs provide the flexibility needed for diverse automotive applications.

Professional automotive detailing swabs for manufacturing and maintenance applications

Vehicle sensor systems require regular cleaning to maintain accuracy and reliability. Cotton swabs remove road debris, manufacturing residues, and environmental contaminants from sensor surfaces without damaging delicate components. Clean sensors ensure proper vehicle operation and safety system functionality.

Engine manufacturing involves precision machining and assembly operations that generate metal particles and cutting fluid residues. Cotton swabs remove these contaminants from critical surfaces and apply lubricants to specific locations. This attention to detail ensures engine reliability and performance.

12. Pharmaceutical Manufacturing Sampling

Pharmaceutical manufacturing operates under strict regulatory requirements for contamination control and product purity. Every surface that contacts pharmaceutical products must be thoroughly cleaned and validated. Industrial cotton swabs provide the precision sampling needed for pharmaceutical quality control.

Sterile manufacturing environments require tools that don’t introduce contaminants or compromise sterile conditions. Pharmaceutical-grade cotton swabs undergo extensive validation to ensure they meet FDA requirements for pharmaceutical manufacturing. These tools enable effective sampling while maintaining regulatory compliance.

Quality control testing requires accurate sampling of surfaces and products for laboratory analysis. Cotton swabs collect samples for microbiological testing, residue analysis, and cleaning validation without introducing false positives. The reliable sampling ensures pharmaceutical products meet safety and efficacy standards.

13. Cleanroom Operations

Cleanroom manufacturing requires specialized tools that don’t generate particles or introduce contaminants. Low-lint cotton swabs are essential for cleaning in these controlled environments where even microscopic particles can affect product quality.

Cleanroom swabs undergo special processing to minimize particle generation during use. The cotton tips are tightly wound and the handles are designed to prevent material shedding. This careful construction ensures that cleaning operations don’t compromise the cleanroom environment.

Different cleanroom classifications require different swab specifications and validation procedures. Class 100 cleanrooms demand the lowest particle generation, while Class 10,000 cleanrooms allow slightly higher levels. Swab selection must match the cleanroom requirements to maintain environmental standards.

14. Equipment Calibration and Maintenance

Precision manufacturing equipment requires regular calibration and maintenance to ensure accurate operation. Cotton swabs clean optical components, remove debris from mechanical parts, and apply lubricants to moving mechanisms. This maintenance ensures continued accuracy and extends equipment service life.

Calibration procedures often require cleaning of reference surfaces and optical components to maintain measurement accuracy. Cotton swabs provide the gentle cleaning action needed without disturbing calibration settings. Clean equipment produces more accurate results and requires less frequent recalibration.

Preventive maintenance programs rely on cotton swabs for routine cleaning and lubrication tasks. The precision application prevents over-lubrication while ensuring adequate protection for moving parts. Regular maintenance with appropriate tools extends equipment life and reduces unexpected failures.

15. Coating Application

Manufacturing processes often require precise coating application for protection, appearance, or functional properties. Cotton swabs enable controlled placement of protective coatings, release agents, and specialized treatments in areas where spray or dip methods are impractical.

Coating application with cotton swabs allows for complex geometries and selective treatment of specific areas. The absorbent tips hold coating materials effectively while providing controlled release during application. This precision ensures complete coverage while minimizing waste of expensive coating materials.

Different coating types require specific application techniques and environmental conditions. Some coatings must be applied in thin, even layers, while others require building up thickness through multiple applications. Cotton swabs accommodate these variations while maintaining application precision.

16. Solvent Application for Cleaning

Different manufacturing contaminants require specific solvents for effective removal. Cotton swabs enable precise solvent application without waste or environmental exposure. This targeted approach is more effective and economical than spray or immersion cleaning methods.

Solvent cleaning with cotton swabs allows for selective cleaning of specific areas without affecting surrounding materials. This precision is important when cleaning assembled products where some components must remain untreated. The controlled application prevents damage to sensitive materials.

Safety considerations are paramount when using solvents with cotton swabs. Proper ventilation, personal protective equipment, and disposal procedures must be followed to protect personnel and the environment. Training in solvent safety is essential for all users.

17. Assembly Line Quality Inspection

Manufacturing quality control requires thorough inspection of products and components throughout the production process. Cotton swabs clean inspection areas and remove debris that could obscure defects or interfere with measurement equipment.

Quality inspection often reveals contamination that must be removed before products can pass inspection criteria. Cotton swabs provide immediate cleaning capability without removing parts from the production line. This efficiency maintains production flow while ensuring quality standards are met.

Inspection procedures must be documented and repeatable to ensure consistent results. Cotton swab cleaning techniques should be standardized and included in quality control procedures. This documentation ensures that all personnel follow the same cleaning methods.

18. Precision Instrument Maintenance

Manufacturing relies on precision instruments for measurement, control, and quality assurance. These instruments require regular cleaning to maintain accuracy and reliability. Cotton swabs clean optical components, remove debris from mechanical parts, and apply protective treatments.

Instrument maintenance with cotton swabs ensures continued accuracy and extends service life. The gentle cleaning action preserves delicate components while removing contaminants that could affect performance. Regular maintenance reduces calibration drift and prevents unexpected failures.

Maintenance procedures should be documented and scheduled to ensure consistent instrument performance. Cotton swab cleaning techniques should be included in maintenance protocols with specific procedures for different instrument types. This standardization ensures reliable results across all equipment.

19. Final Product Cleaning

Manufacturing processes often leave residues on finished products that must be removed before packaging and shipment. Cotton swabs provide final cleaning to remove fingerprints, assembly aids, and other contaminants that could affect product appearance or performance.

Final product cleaning requires gentle yet effective action that removes contaminants without damaging finished surfaces or protective coatings. Cotton swabs provide the precision needed to clean complex geometries and delicate surfaces. This attention to detail ensures products meet customer expectations for quality and appearance.

Quality standards for final product cleaning must be clearly defined and consistently applied. Cotton swab cleaning procedures should be documented with specific techniques for different product types. This standardization ensures that all products meet the same cleanliness standards.

High-quality industrial cotton swabs for professional manufacturing use

Industry-Specific Applications

Electronics Manufacturing

Electronics manufacturing presents unique challenges that require specialized cleaning and maintenance tools. Components are increasingly miniaturized while becoming more sensitive to contamination and static electricity. Industrial cotton swabs address these challenges with precision cleaning capability and static dissipative properties.

Modern electronic devices contain components that operate at microscopic scales where even tiny particles can cause failures. Cotton swabs reach into tight spaces between components and clean delicate surfaces without causing damage. The controlled cleaning action prevents short circuits and component displacement during maintenance operations.

Static electricity control is paramount in electronics manufacturing. ESD-safe cotton swabs with conductive handles safely dissipate static charges while cleaning sensitive components. This protection is essential for preserving expensive integrated circuits and ensuring product reliability.

Flux removal is a critical step in electronics assembly that requires thorough cleaning without component damage. Cotton swabs with appropriate solvents remove flux residues completely while protecting delicate solder joints and component markings. The precision cleaning ensures long-term reliability and prevents corrosion.

Automotive Industry

Automotive manufacturing combines traditional mechanical systems with sophisticated electronic components and sensors. This diversity requires versatile cleaning tools that work effectively across different materials and applications. Industrial cotton swabs provide the flexibility needed for modern automotive production.

Vehicle sensor systems are critical for safety and performance but require regular cleaning to maintain accuracy. Cotton swabs remove manufacturing residues, environmental contaminants, and assembly aids from sensor surfaces without damaging delicate components. Clean sensors ensure proper vehicle operation and regulatory compliance.

Engine manufacturing involves precision machining operations that generate metal particles and cutting fluid residues. These contaminants must be completely removed before assembly to prevent premature wear and failure. Cotton swabs provide precise cleaning that reaches into complex geometries and removes all traces of contamination.

Paint and coating operations in automotive manufacturing require careful surface preparation and touch-up capabilities. Cotton swabs enable precise application of primers, paints, and protective coatings in areas where spray methods are impractical. The controlled application ensures consistent quality and appearance.

Aerospace and Defense

Aerospace manufacturing operates under the most stringent quality requirements where component failures can have catastrophic consequences. Every aspect of production must meet exacting standards for cleanliness, reliability, and performance. Industrial cotton swabs play a critical role in maintaining these standards.

Aerospace components operate in extreme environments with temperature variations, vibration, and chemical exposure. Proper cleaning and maintenance with appropriate tools extends component life and ensures reliable operation throughout the service life. Cotton swabs provide the precision needed for aerospace quality standards.

Critical aerospace systems require contamination-free assembly and maintenance procedures. Cleanroom-grade cotton swabs ensure that cleaning operations don’t introduce particles that could cause system failures. This level of cleanliness is essential for mission-critical applications where failure is not acceptable.

Sealant application in aerospace manufacturing requires precise placement and complete coverage to prevent leaks that could compromise safety. Cotton swabs enable controlled sealant application in complex geometries where conventional methods are inadequate. The precision application ensures reliable sealing performance.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing operates under strict regulatory oversight with requirements for contamination control and product purity. Every surface that contacts pharmaceutical products must be thoroughly cleaned and validated according to FDA guidelines. Industrial cotton swabs provide the precision cleaning needed for pharmaceutical compliance.

Sterile manufacturing environments require tools that don’t introduce contaminants or compromise sterile conditions. Pharmaceutical-grade cotton swabs undergo extensive validation to ensure they meet regulatory requirements for pharmaceutical manufacturing. These tools enable effective cleaning while maintaining compliance.

Quality control testing in pharmaceutical manufacturing requires accurate sampling for laboratory analysis. Cotton swabs collect samples for microbiological testing, residue analysis, and cleaning validation without introducing false positives. The reliable sampling ensures pharmaceutical products meet safety and efficacy standards.

Cleaning validation is a critical requirement in pharmaceutical manufacturing that demonstrates the effectiveness of cleaning procedures. Cotton swabs provide standardized sampling methods that produce reproducible results for regulatory submissions. The documented procedures ensure consistent compliance with FDA requirements.

Choosing the Right Industrial Cotton Swabs

Selecting appropriate cotton swabs for manufacturing applications requires careful consideration of multiple factors that affect performance and safety. The substrate being cleaned, contamination type, cleaning solvents, and environmental conditions all influence the optimal choice.

Substrate Considerations: Different materials require different cleaning approaches to prevent damage while achieving effective contamination removal. Smooth, hard surfaces like metals and ceramics can accommodate more aggressive cleaning action, while soft materials like plastics and elastomers require gentler treatment.

Rough or textured surfaces present special challenges that may require stronger swab materials to withstand abrasive contact. Polyester swabs offer superior durability for these applications while maintaining cleaning effectiveness. The material choice must balance cleaning performance with substrate protection.

Contamination Analysis: Understanding the type and extent of contamination guides swab selection and cleaning procedures. Light contamination like dust and fingerprints can be removed with gentle cleaning action, while heavy contamination like adhesives and coatings requires more aggressive treatment.

Organic contamination typically responds well to solvent cleaning, while inorganic particles may require mechanical action for removal. The cleaning method must match the contamination characteristics to achieve effective results without spreading contaminants to clean areas.

Solvent Compatibility: Chemical compatibility between swab materials and cleaning solvents is essential for effective cleaning and safety. Cotton swabs work well with water-based cleaners and alcohols but may degrade in strong solvents like ketones and aromatics.

Polyester and foam swabs offer superior chemical resistance for applications requiring harsh solvents. The material selection must consider both immediate compatibility and long-term stability to prevent swab degradation during use.

Environmental Requirements: Manufacturing environments impose specific requirements that affect swab selection. Cleanroom applications require low-lint swabs with minimal particle generation, while static-sensitive environments need ESD-safe swabs with conductive handles.

Temperature and humidity conditions can affect swab performance and shelf life. High-temperature applications may require synthetic materials that maintain integrity under thermal stress. Storage conditions must also be considered to prevent degradation before use.

Best Practices for Industrial Cotton Swab Use

Effective use of industrial cotton swabs requires proper techniques and procedures that maximize cleaning effectiveness while preventing damage and contamination. Following established best practices ensures consistent results and maintains safety standards.

Preparation Procedures: Always verify that swabs are appropriate for the specific application before use. Check material compatibility with cleaning solvents and ensure that swabs are clean and free from manufacturing contaminants. Use fresh swabs for each cleaning operation to prevent cross-contamination between different areas or products.

Storage conditions affect swab performance and shelf life. Keep swabs in clean, dry environments away from contamination sources. Sealed packaging should remain intact until use to prevent contamination. Rotate stock to ensure oldest materials are used first.

Application Techniques: Apply gentle, controlled pressure during cleaning operations to prevent damage to delicate surfaces or components. Use smooth, consistent motions that lift contaminants away from surfaces rather than spreading them around. Work from clean areas toward contaminated areas to prevent contamination spread.

Avoid excessive force that could damage components or leave fibers behind. The cleaning action should be sufficient to remove contaminants without causing surface damage or component displacement. Multiple gentle passes are more effective than single aggressive actions.

Solvent Application: Apply cleaning solvents to the swab rather than directly to the component when possible. This approach provides better control over solvent quantity and prevents excess liquid from reaching sensitive areas. Allow solvents to penetrate contamination before beginning cleaning action.

Use appropriate solvent quantities to achieve effective cleaning without waste or environmental exposure. Excess solvent can spread contamination or damage sensitive materials. The solvent application should be sufficient for the cleaning task without creating additional problems.

Safety Procedures: Follow all safety requirements for solvent use including proper ventilation, personal protective equipment, and disposal procedures. Many industrial solvents pose health and environmental risks that require careful handling. Training in chemical safety is essential for all personnel using solvents.

Dispose of used swabs according to environmental regulations and company policies. Swabs contaminated with hazardous materials require special disposal procedures. Never reuse swabs as this can spread contamination and compromise cleaning effectiveness.

Quality Standards and Certifications

Industrial cotton swabs must meet various quality standards and certifications depending on their intended applications. Understanding these requirements helps ensure that appropriate products are selected for specific manufacturing needs.

ISO Quality Standards: Many industrial swabs are manufactured according to ISO 9001 quality management standards that ensure consistent quality and performance. These standards require documented procedures, regular audits, and continuous improvement processes that provide confidence in product reliability.

ISO 13485 certification is required for medical device manufacturing and ensures that swabs meet medical industry quality requirements. This certification involves additional testing and validation procedures that demonstrate suitability for medical applications.

Cleanroom Classifications: Swabs used in cleanroom environments must meet specific particle generation limits defined by cleanroom classification standards. Class 100 cleanrooms require the lowest particle generation, while Class 10,000 cleanrooms allow higher levels.

Particle testing procedures measure the number and size of particles generated during swab use. These tests ensure that cleaning operations don’t compromise cleanroom environmental standards. Regular testing verifies continued compliance with cleanroom requirements.

Industry Certifications: Specific industries may require additional certifications that demonstrate compliance with industry standards. Aerospace applications often require AS9100 certification, while pharmaceutical applications need FDA validation.

These certifications involve extensive testing and documentation that demonstrates product suitability for specific applications. The certification process ensures that swabs meet all relevant requirements for safety, performance, and regulatory compliance.

Material Certifications: Some applications require certification of swab materials to ensure they don’t contain prohibited substances or contaminants. RoHS compliance ensures that swabs don’t contain restricted hazardous substances, while USP Class VI certification demonstrates biocompatibility for medical applications.

Material certifications require testing by accredited laboratories and documentation of test results. These certifications provide assurance that swabs are safe for their intended applications and won’t introduce harmful substances.

Cost Considerations and ROI

While industrial cotton swabs may have higher initial costs than household versions, they provide significant value through improved performance, reliability, and efficiency. The investment in quality swabs typically pays for itself through reduced rework, improved product quality, and increased productivity.

Performance Benefits: Quality industrial swabs clean more effectively and consistently than general-purpose alternatives. This improved performance reduces the time and effort required for cleaning operations while achieving better results. The efficiency gains often justify the additional cost through labor savings.

Specialized swabs designed for specific applications work faster and more effectively than general-purpose tools. The improved performance reduces cleaning time and improves consistency across different operators and shifts. These benefits translate directly into cost savings and quality improvements.

Quality Improvements: Proper cleaning with appropriate tools reduces defect rates and improves product quality throughout the manufacturing process. Higher quality products command better prices and reduce warranty costs. The quality improvement often provides the largest return on investment for premium cleaning tools.

Reduced rework and scrap rates directly impact manufacturing costs and profitability. Quality swabs help prevent contamination-related defects that require expensive rework or product disposal. The cost avoidance often exceeds the additional tool costs by significant margins.

Efficiency Gains: Specialized swabs enable faster, more effective cleaning operations that improve overall manufacturing efficiency. Reduced cleaning time allows more productive use of equipment and personnel. The efficiency improvements contribute to higher throughput and lower unit costs.

Standardized cleaning procedures with appropriate tools reduce variability and training requirements. Consistent results across different operators and shifts improve quality and reduce supervision requirements. These benefits contribute to overall operational efficiency.

Long-term Value: Quality industrial swabs often provide better long-term value through consistent performance and reliability. While initial costs may be higher, the total cost of ownership is often lower due to improved effectiveness and reduced replacement frequency.

Supplier relationships with quality manufacturers provide access to technical support and product development resources. These relationships can lead to customized solutions and continuous improvement opportunities that provide ongoing value.

Future Trends in Industrial Cotton Swabs

The industrial cotton swab market continues evolving with advancing technology and changing manufacturing requirements. New materials, designs, and applications are constantly being developed to meet emerging needs in modern manufacturing.

Advanced Materials: Research into new synthetic materials offers improved performance characteristics like enhanced chemical resistance, reduced particle generation, and better thermal stability. These materials enable use in more demanding applications while maintaining the benefits of traditional cotton.

Nanofiber technology is being applied to swab construction to create materials with superior cleaning performance and contamination capture capability. These advanced materials offer improved effectiveness while reducing environmental impact through better biodegradability.

Specialized Designs: Manufacturers are developing swabs with specialized tip shapes and sizes optimized for specific applications. Custom geometries improve cleaning effectiveness and enable access to previously unreachable areas in complex assemblies.

Ergonomic handle designs reduce operator fatigue and improve precision during extended use. These improvements enhance productivity and reduce the risk of repetitive stress injuries in manufacturing environments.

Automation Integration: Some manufacturers are developing swabs designed for use with automated cleaning systems. These swabs maintain consistent performance while enabling automated operations that improve efficiency and repeatability.

Robotic cleaning systems require swabs with predictable performance characteristics and standardized dimensions. The development of automation-compatible swabs enables more widespread adoption of automated cleaning processes.

Sustainability Initiatives: Environmental concerns are driving development of more sustainable swab materials and manufacturing processes. Biodegradable materials and renewable resources are being incorporated into swab construction to reduce environmental impact.

Recycling programs for used swabs are being developed to reduce waste and recover valuable materials. These initiatives help manufacturers meet sustainability goals while maintaining cleaning performance standards.

Conclusion

Industrial cotton swabs are indispensable precision tools in modern manufacturing environments. Their versatility, effectiveness, and reliability make them essential for maintaining quality standards and ensuring product reliability across diverse industries. From electronics assembly to aerospace manufacturing, these specialized tools provide the precision and performance that demanding applications require.

The 19 professional applications outlined in this comprehensive guide demonstrate the extensive range of uses for industrial cotton swabs in manufacturing environments. Each application requires specific considerations for material selection, technique, and safety procedures. Understanding these requirements ensures optimal results while preventing damage to valuable components and maintaining safety standards.