Have you ever wondered where Q-tips are made while reaching for that familiar blue and white box in your medicine cabinet? You’re not alone. In today’s world of global supply chains and increasing consumer awareness about product origins, understanding where our everyday items come from has become more important than ever.

The question of Q-tips manufacturing locations touches on broader concerns about supply chain transparency, product quality, and ethical sourcing practices. As consumers become more conscious about the products they purchase, knowing the manufacturing origins of cotton swabs has evolved from simple curiosity to a matter of informed decision-making.

Quick Answer: Where Q-tips Manufacturing Happens Today

Before diving deep into the fascinating history and complex global landscape of cotton swab manufacturing, here’s what you need to know about where Q-tips are made:

Current Q-tips Production:

- Primary manufacturing facility: Las Piedras, Puerto Rico

- Brand owner: Elida Beauty (formerly part of Unilever)

- Raw cotton sourcing: Global suppliers including India, China, and USA

- Production focus: Consolidated manufacturing for efficiency and quality control

Global Cotton Swab Manufacturing:

- China dominates international cotton swab production

- India serves as both raw material supplier and manufacturer

- Vietnam, Brazil, and Mexico are significant exporters

- Sustainable and organic cotton swab production is growing worldwide

Supply Chain Transparency Trends:

- Increasing demand for ethical sourcing certifications

- Growing focus on sustainable manufacturing practices

- Enhanced quality control and ISO certifications

- Consumer preference for traceable product origins

Now, let’s explore the complete story behind Q-tips manufacturing and what it means for today’s conscious consumers.

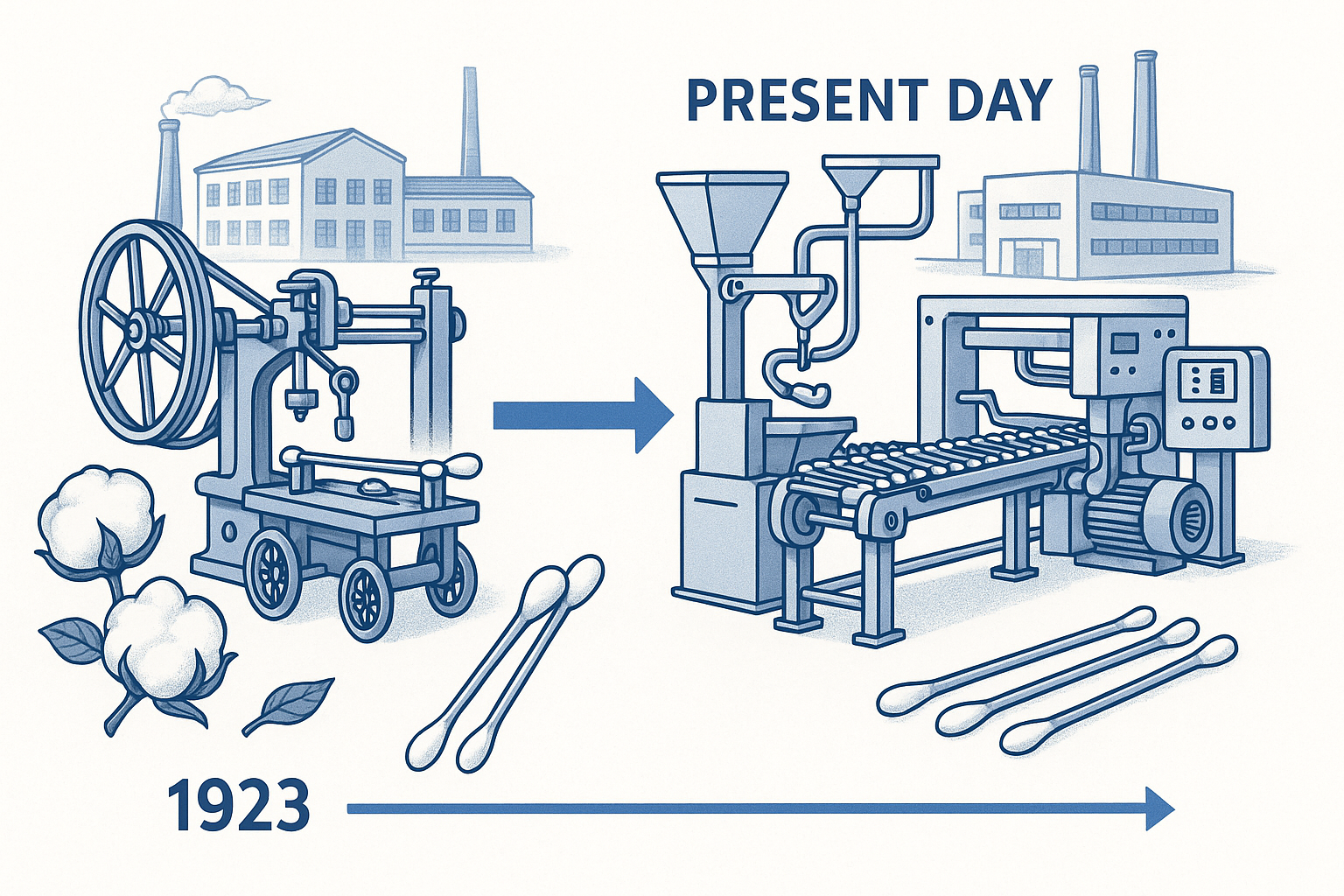

Section 1: Q-tips Production History – U.S.-Based Origins

The story of Q-tips manufacturing begins with a simple observation that would revolutionize personal care. In 1923, Polish-American inventor Leo Gerstenzang watched his wife carefully attaching bits of cotton to toothpicks to clean their baby’s ears. This everyday moment sparked an idea that would create one of America’s most recognizable consumer products.

The Birth of American Cotton Swab Manufacturing

Gerstenzang founded the Leo Gerstenzang Infant Novelty Company in New York City, establishing the first cotton swab manufacturing facility in the United States. The original product, initially called “Baby Gays,” represented a significant innovation in baby care accessories. By 1926, the name evolved to “Q-tips Baby Gays,” and eventually simply “Q-tips,” with the “Q” standing for quality.

The early Q-tips production was entirely American-based, reflecting the manufacturing capabilities and quality standards of the era. The company’s commitment to domestic production aligned with the broader American manufacturing boom of the 1920s and 1930s, when “Made in USA” represented the gold standard for consumer products.

Manufacturing Evolution and Corporate Changes

As demand grew throughout the 1940s, Q-tips manufacturing moved from New York City to Long Island City, New York in 1948. The facility operated on a “round-the-clock, three-shift basis” to meet growing consumer demand.

The 1960s brought significant changes when Chesebrough-Ponds acquired the company in 1962, moving production to Jefferson City, Missouri. In 1974, a portion of production moved to Las Piedras, Puerto Rico, and by 2000, all Q-tips manufacturing was consolidated at the Puerto Rico facility.

Section 2: Where Q-tips Are Made Today (USA or Overseas)

Currently, Q-tips are primarily manufactured in Las Piedras, Puerto Rico, at a facility operated by Elida Beauty. This transition reflects broader trends in global production and supply chain optimization that have reshaped American consumer goods manufacturing.

Why Puerto Rico for Q-tips Manufacturing?

The Puerto Rico location offers several strategic advantages:

Economic Benefits: Competitive manufacturing costs while maintaining access to U.S. markets without international trade barriers, preserving the “Made in USA” designation.

Regulatory Compliance: As a U.S. territory, Puerto Rico operates under the same FDA regulations and quality standards that govern mainland U.S. manufacturing.

Logistical Advantages: Efficient access to both North American and international markets while maintaining centralized production control.

Supply Chain Complexity

While Q-tips are made in Puerto Rico, the complete supply chain involves global sourcing. The cotton used comes from various suppliers, including major cotton-producing regions in India, China, and the United States. This diversified sourcing strategy ensures consistent supply availability and quality while managing cost considerations.

Section 3: The Rise of International Cotton Swab Manufacturing

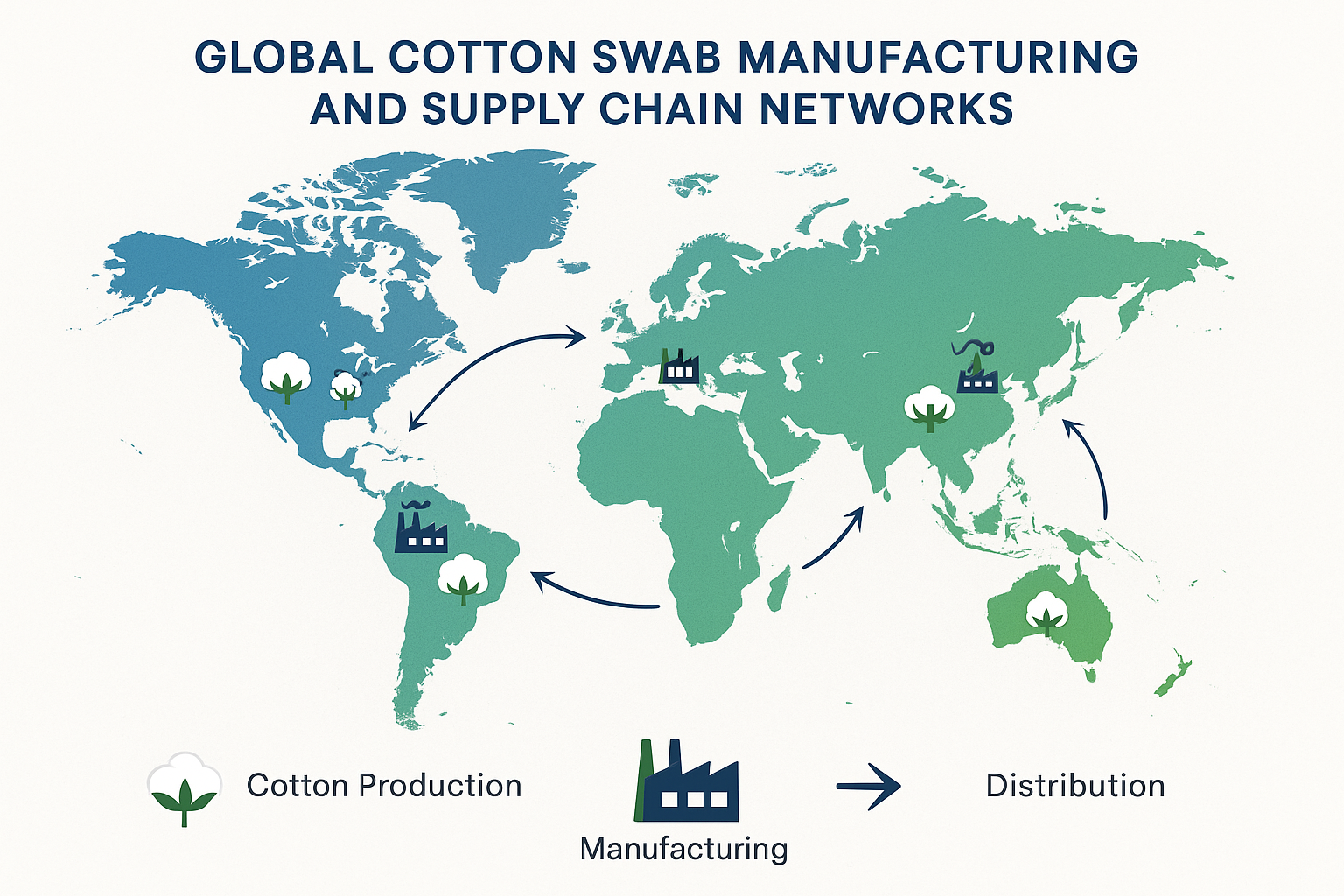

Global cotton swab manufacturing and supply chain networks illustrating the international scope of modern cotton swab production and distribution

While Q-tips maintains its production in Puerto Rico, the broader cotton swab manufacturing landscape has undergone dramatic transformation. The rise of international manufacturing has created a complex global ecosystem where cotton swabs are produced across multiple continents.

China’s Manufacturing Dominance

China has emerged as the undisputed leader in international cotton swab manufacturing, accounting for a significant portion of global production. The country’s manufacturing dominance stems from:

- Industrial Clusters: Concentrated manufacturing clusters in the Pearl River Delta region

- Scale Advantages: Some of the world’s largest cotton swab production facilities

- Technology Investment: Advanced automated production equipment and quality control systems

- Supply Chain Integration: Vertically integrated production controlling everything from cotton processing to final packaging

India’s Growing Role

India represents another major force in international cotton swab manufacturing, leveraging its position as one of the world’s largest cotton producers. The country offers:

- Raw Material Access: Direct access to high-quality cotton, reducing supply chain costs

- Cost-Effective Production: Competitive labor costs and efficient manufacturing processes

- Quality Capabilities: Sophisticated quality control systems and international certifications

- Export Growth: Significant exporter serving markets in Asia, Africa, and Western countries

Other Manufacturing Regions

Vietnam, Brazil, Mexico, and Nigeria have also emerged as significant players in the global cotton swab manufacturing landscape, each serving both domestic and regional markets with increasing sophistication.

Section 4: Ethical Sourcing, Sustainability, and Certifications

Key sustainability and quality certifications that guide ethical cotton swab manufacturing, including GOTS organic standards, ISO quality management, Fair Trade practices, and environmental sustainability initiatives

As consumers become increasingly conscious about environmental and social impact, ethical cotton swab manufacturing has evolved from a niche concern to a mainstream expectation.

Key Certifications

GOTS (Global Organic Textile Standard): The most comprehensive standard for organic cotton products, requiring at least 70% organic fibers and strict environmental criteria.

ISO Certifications: Including ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety).

Fair Trade Certification: Ensures cotton farmers receive fair prices and production meets social and environmental standards.

Sustainability Trends

Modern environmentally responsible cotton swab manufacturing addresses:

- Carbon Footprint Reduction: Energy-efficient processes and renewable energy sources

- Waste Minimization: Advanced manufacturing processes and recycling programs

- Water Conservation: Water recycling systems and efficient cleaning processes

- Packaging Sustainability: Recyclable materials and reduced packaging volume

Section 5: SwabMasters’ Commitment to Responsible Production

At SwabMasters, we understand that modern consumers want to know not just where cotton swabs are made, but how they’re made and what values guide the manufacturing process.

Complete Cotton Control

Our vertically integrated cotton swab manufacturing approach sets us apart:

- Premium Cotton Sourcing: Direct relationships with cotton suppliers worldwide

- In-House Cotton Sliver Production: Advanced carding technology that preserves natural cotton properties

- Universal Compatibility: Optimized cotton characteristics for different stick materials

- Quality Assurance: Comprehensive testing at every production stage

Advanced Quality Control

SwabMasters cotton swab manufacturing incorporates:

- Material Testing: Rigorous testing for purity, absorbency, and safety

- Production Monitoring: Real-time quality control across millions of units

- Sterility Protocols: Strict protocols ensuring highest safety standards

- Final Product Verification: Comprehensive testing before distribution

Sustainability Commitment

Our commitment to sustainable cotton swab manufacturing includes:

- Chemical-Free Processing: No-bleaching-agent policy preserving cotton’s natural properties

- Waste Minimization: Comprehensive recycling and repurposing programs

Conclusion: The Future of Cotton Swab Manufacturing

Understanding where cotton swabs are made has evolved beyond simple geographic curiosity. Today’s informed consumers recognize that manufacturing location represents a complex intersection of quality standards, ethical practices, environmental responsibility, and supply chain transparency.

The journey from Q-tips’ American origins in 1923 to today’s global manufacturing landscape illustrates how consumer products have adapted to changing economic realities while striving to maintain quality and safety standards.